How We Work

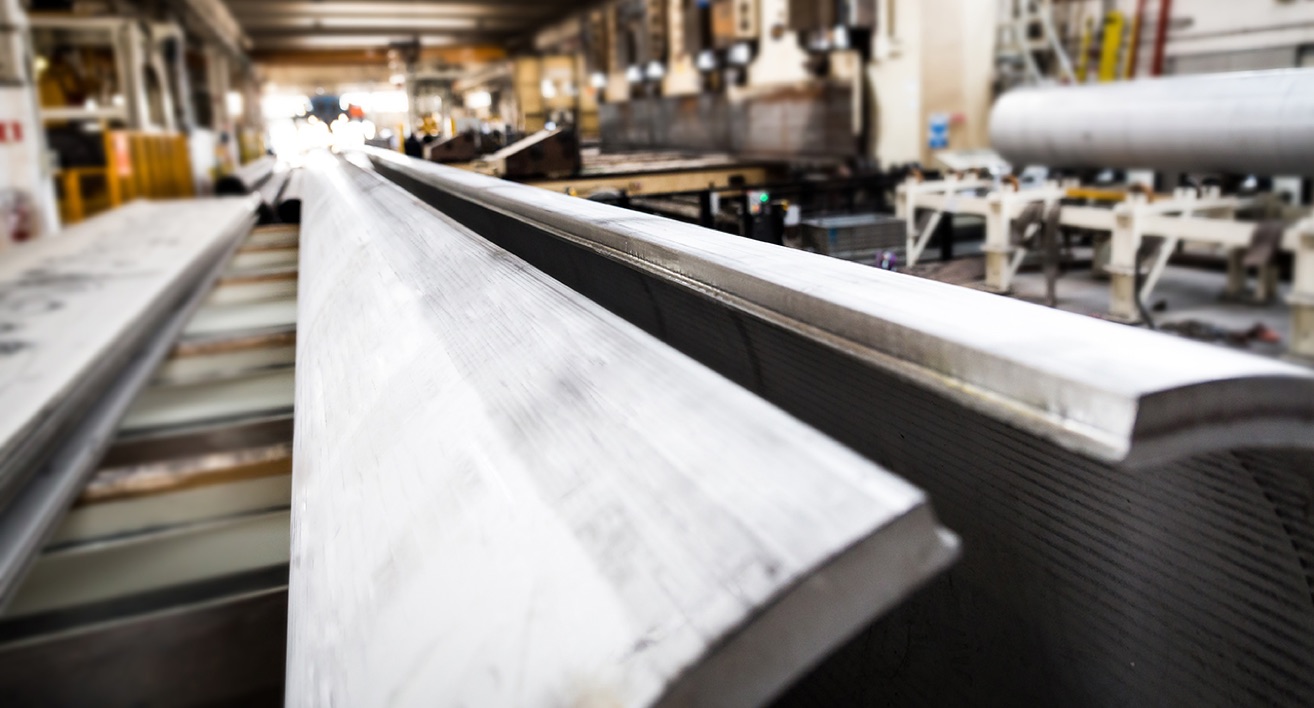

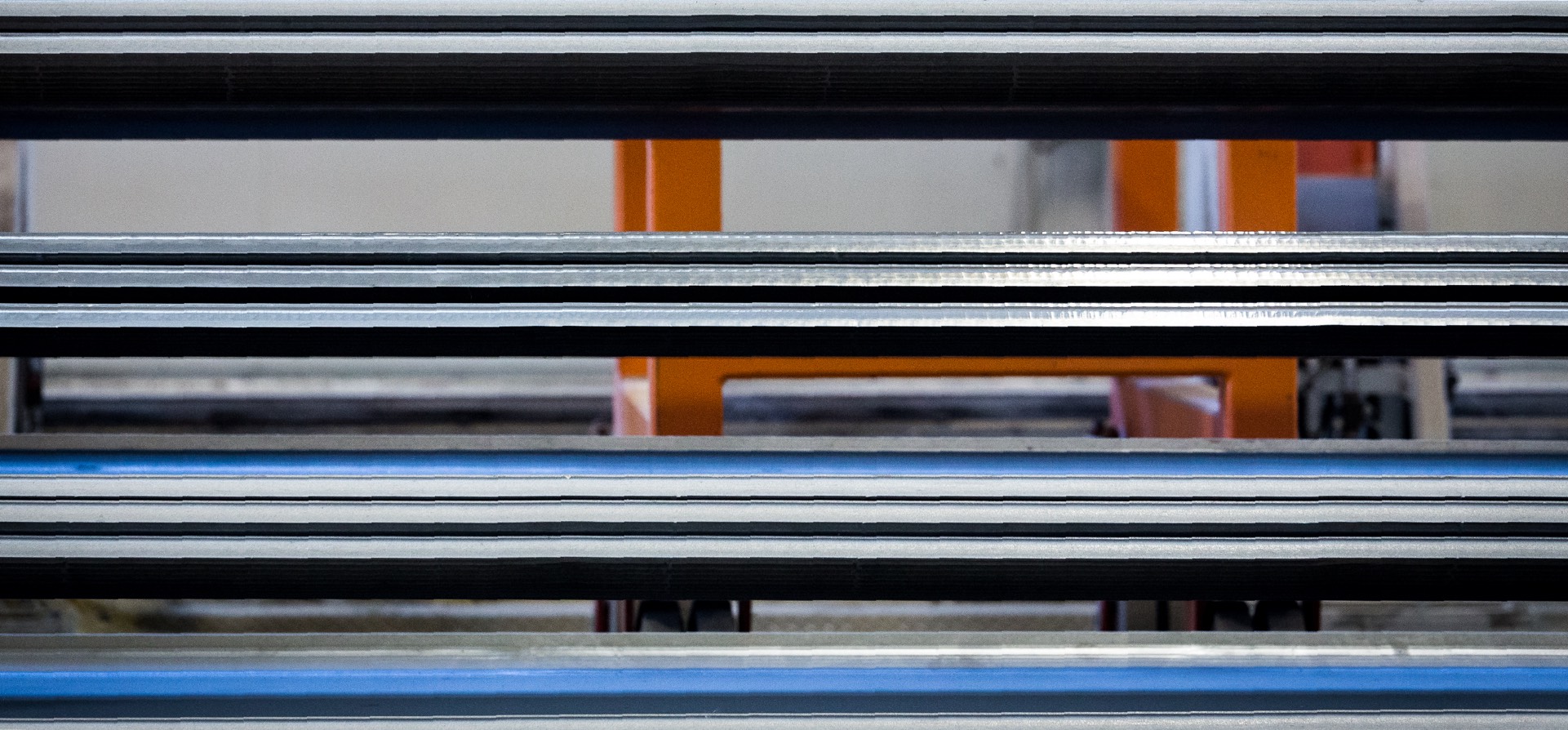

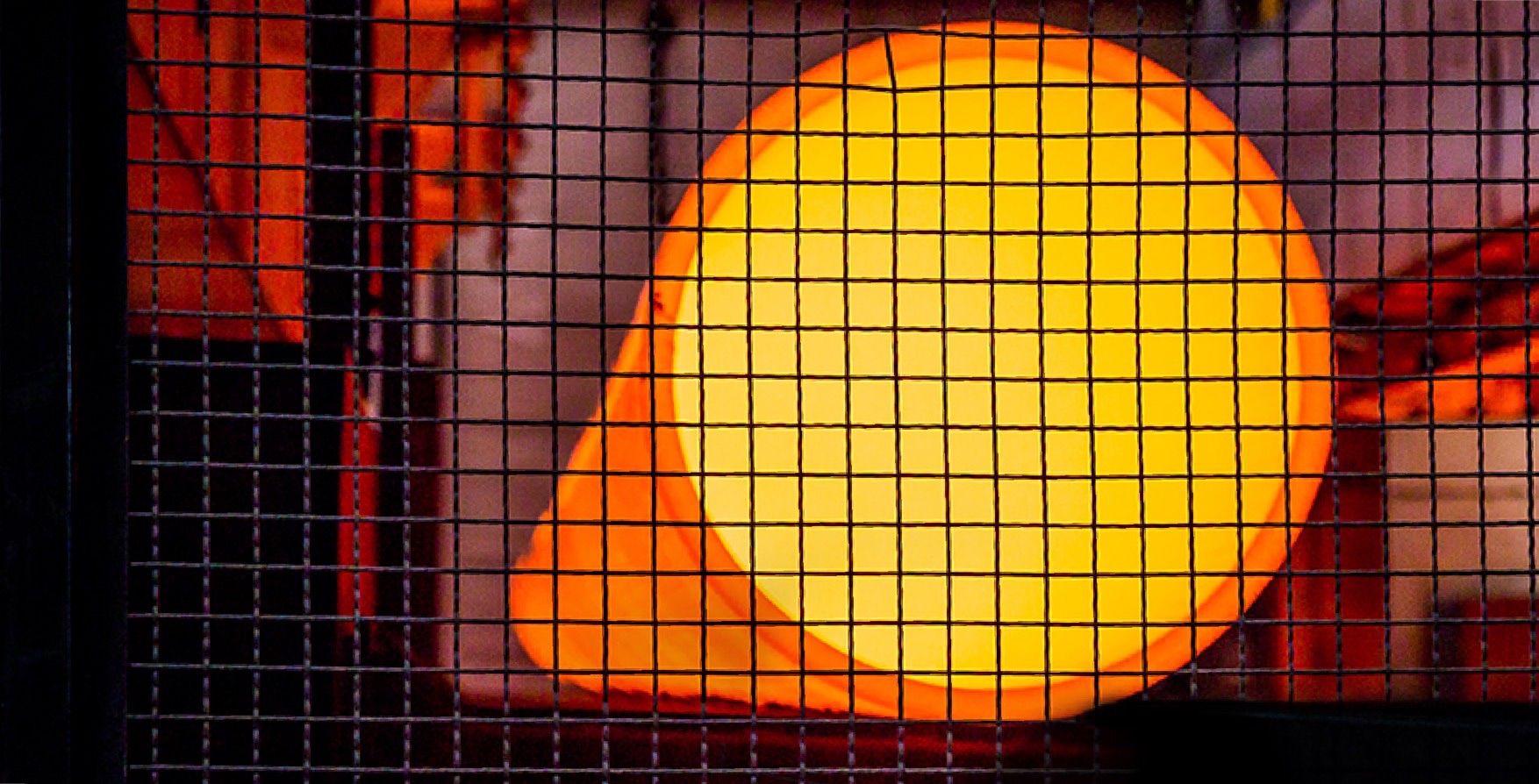

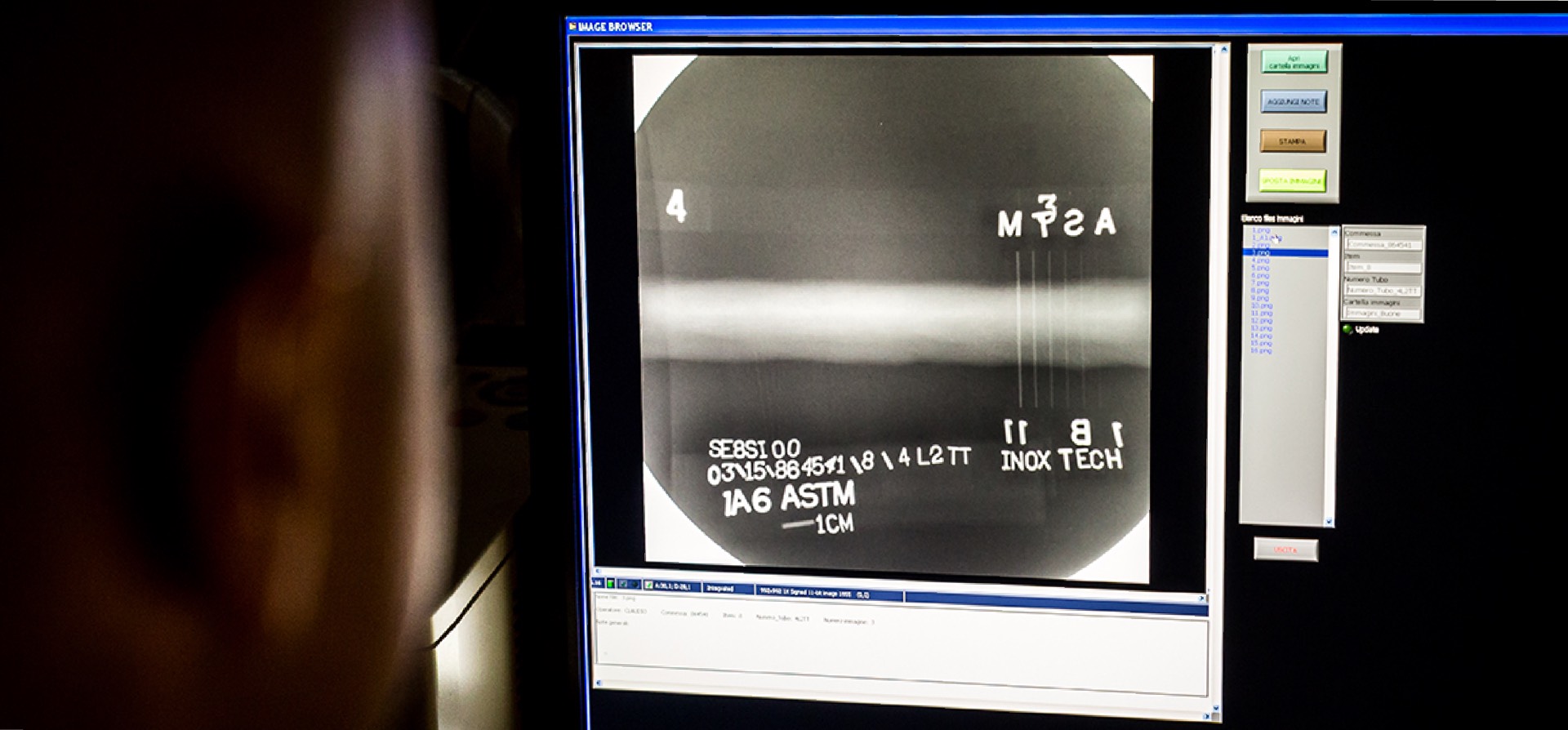

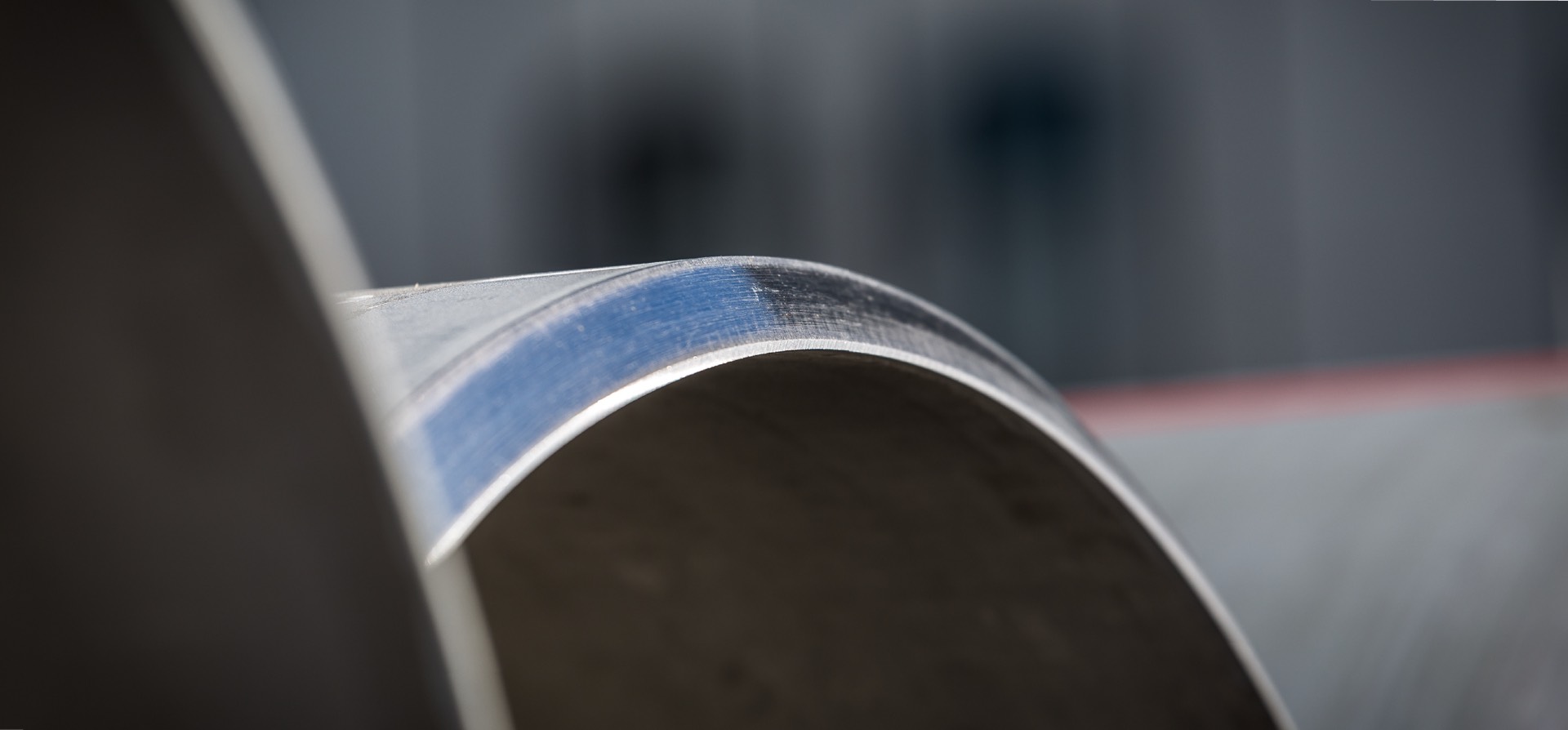

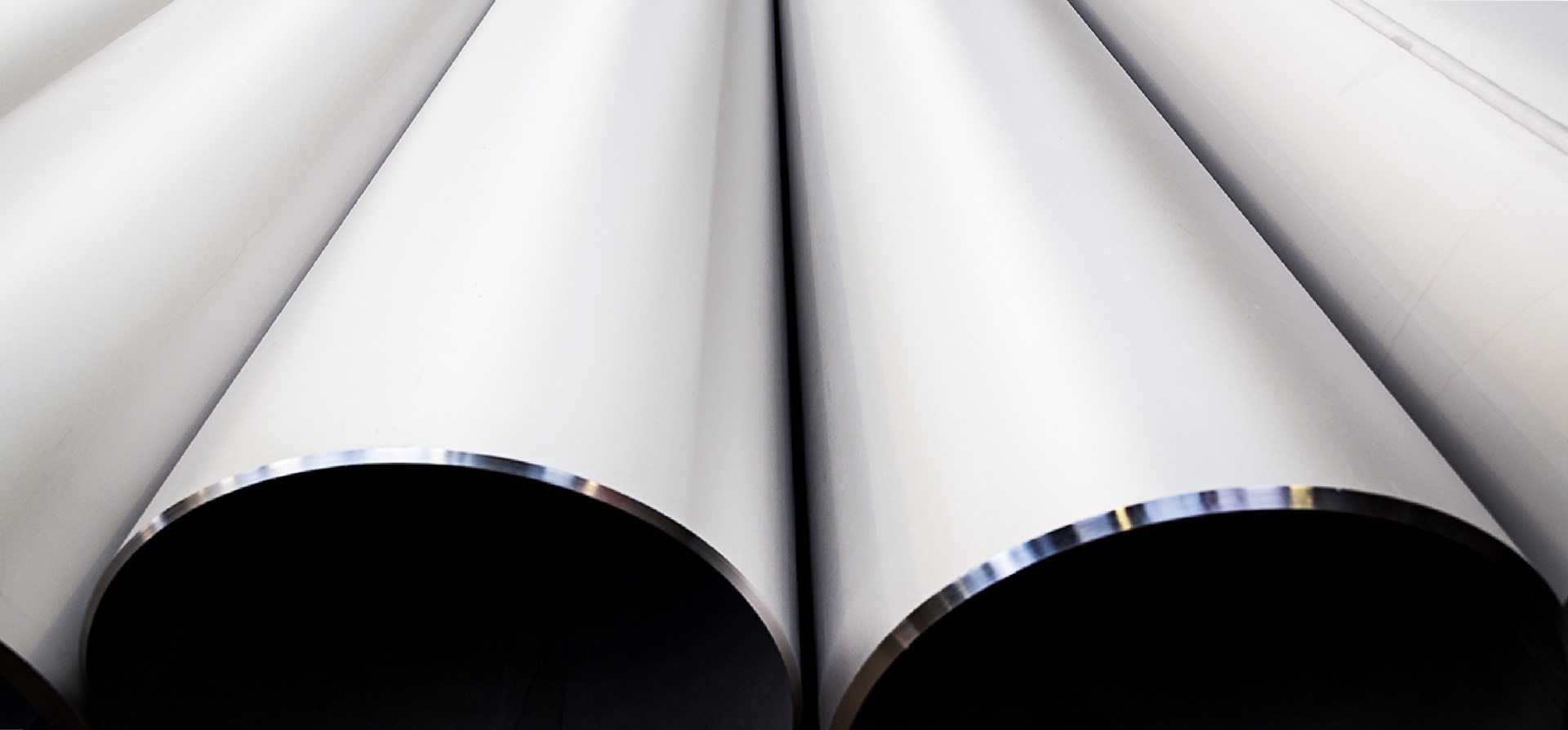

The focus of our business is the manufacturing of high quality longitudinally welded pipes in a wide range of material and size, with demanding tolerances and restrictive requirements. For the production of our pipes we use plates sourced form major steel mills in the world. We apply the most stringent controls during and after production.

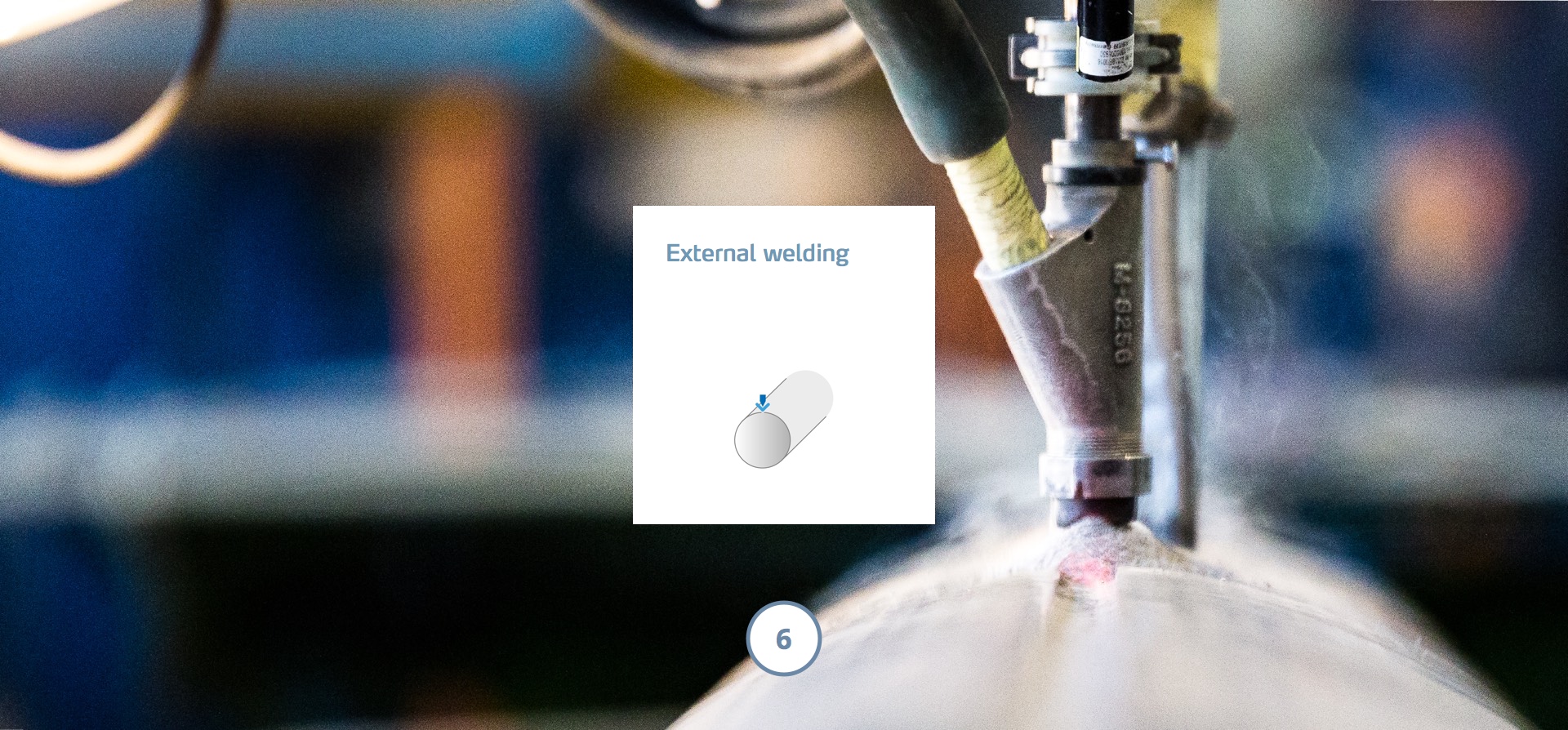

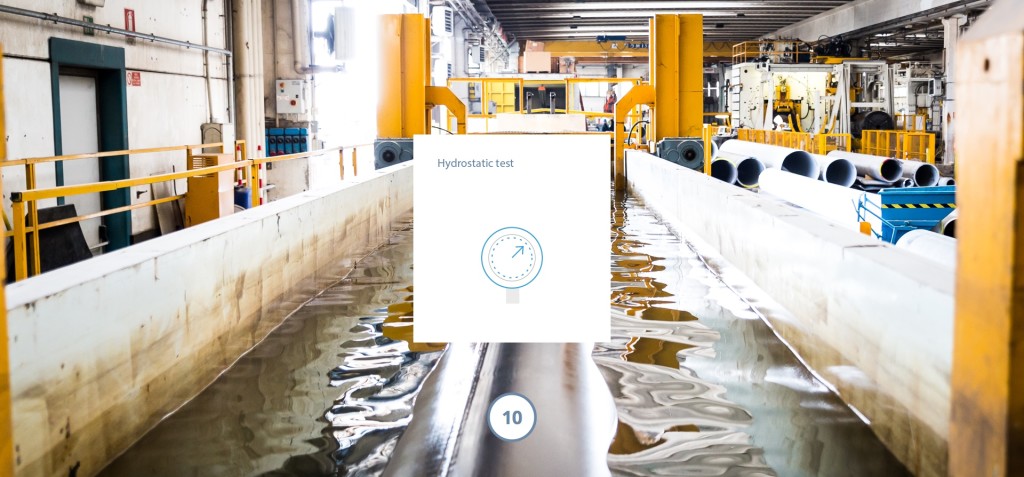

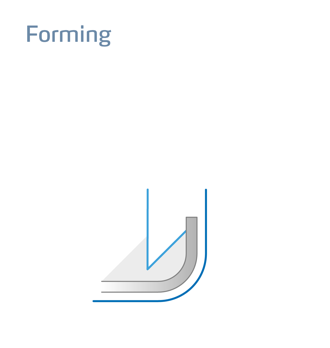

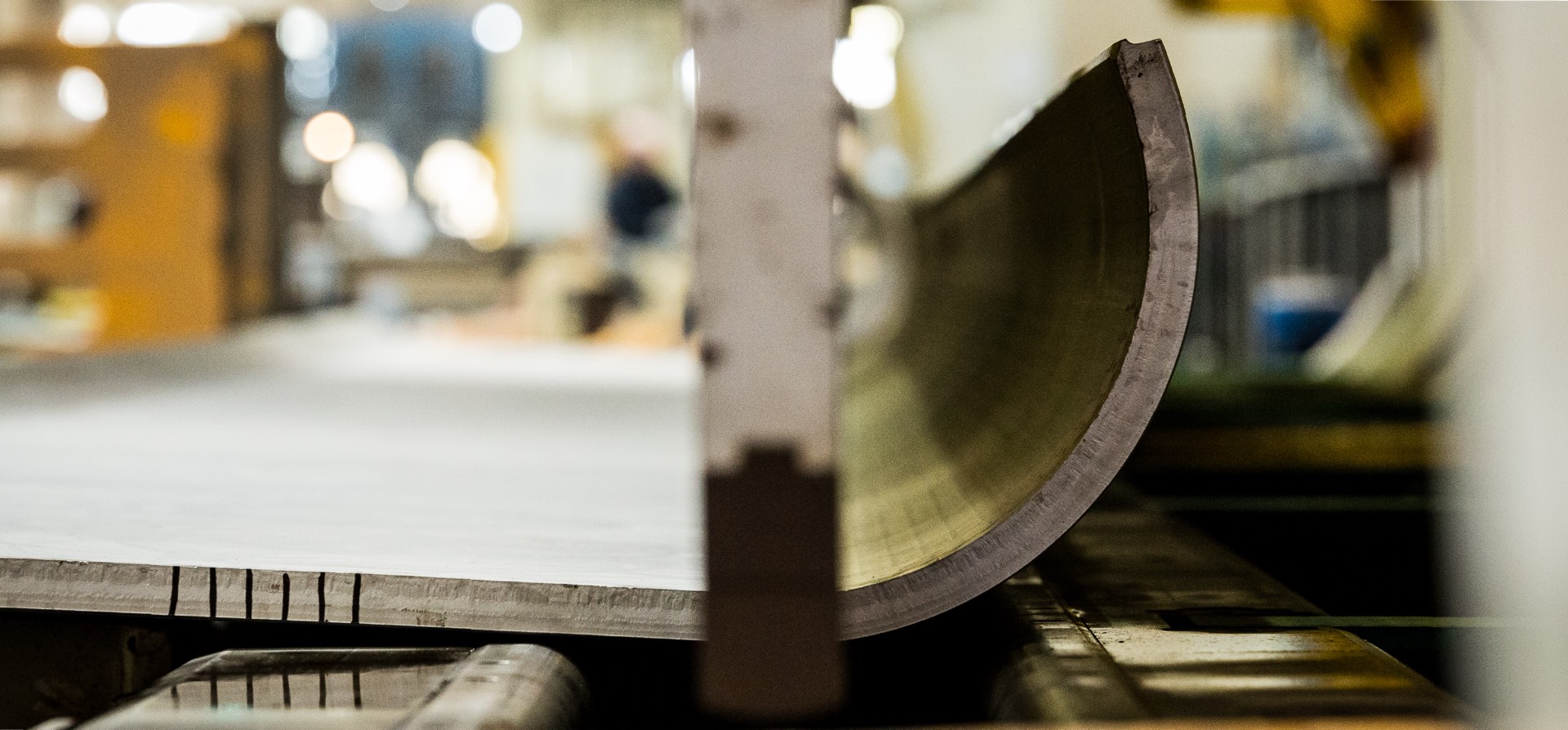

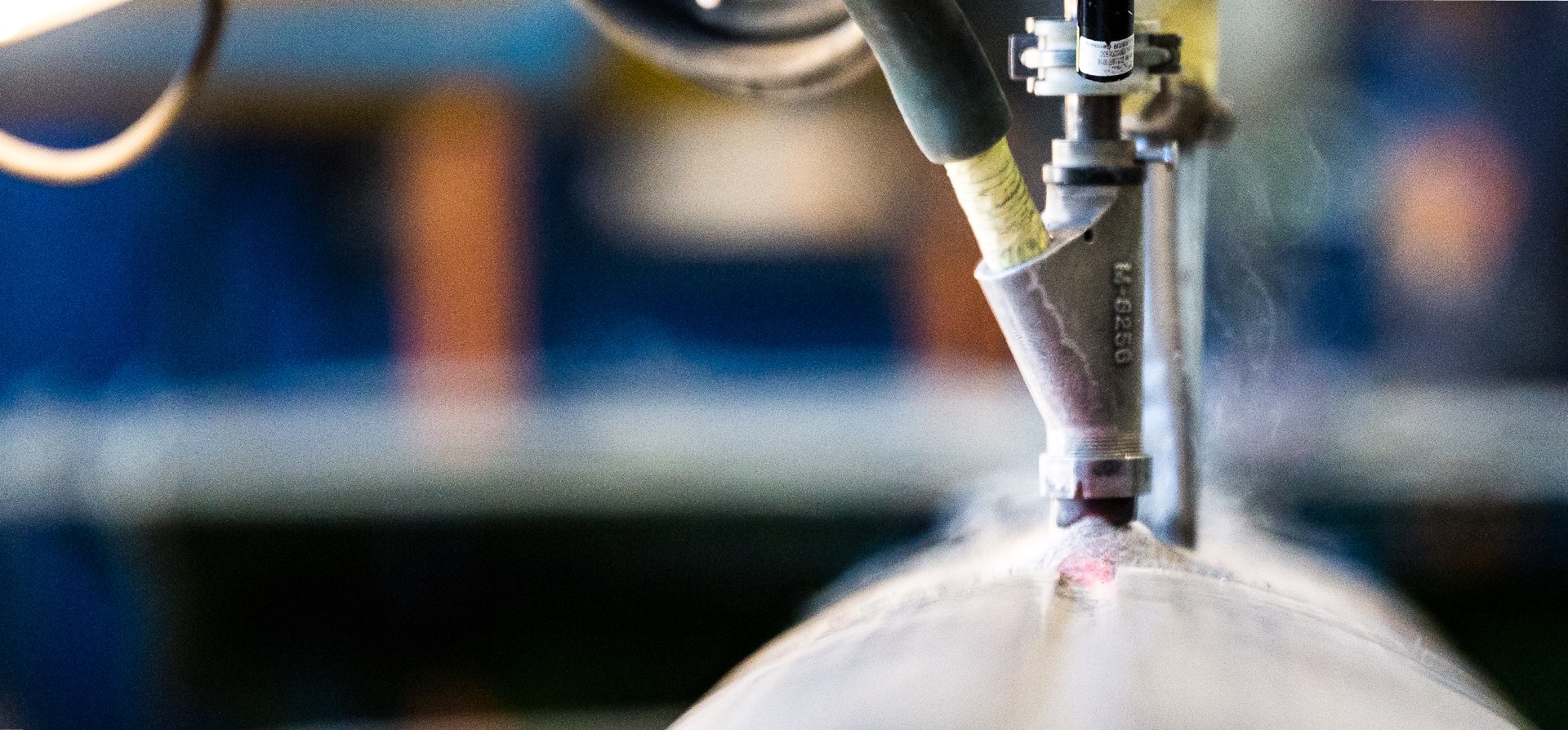

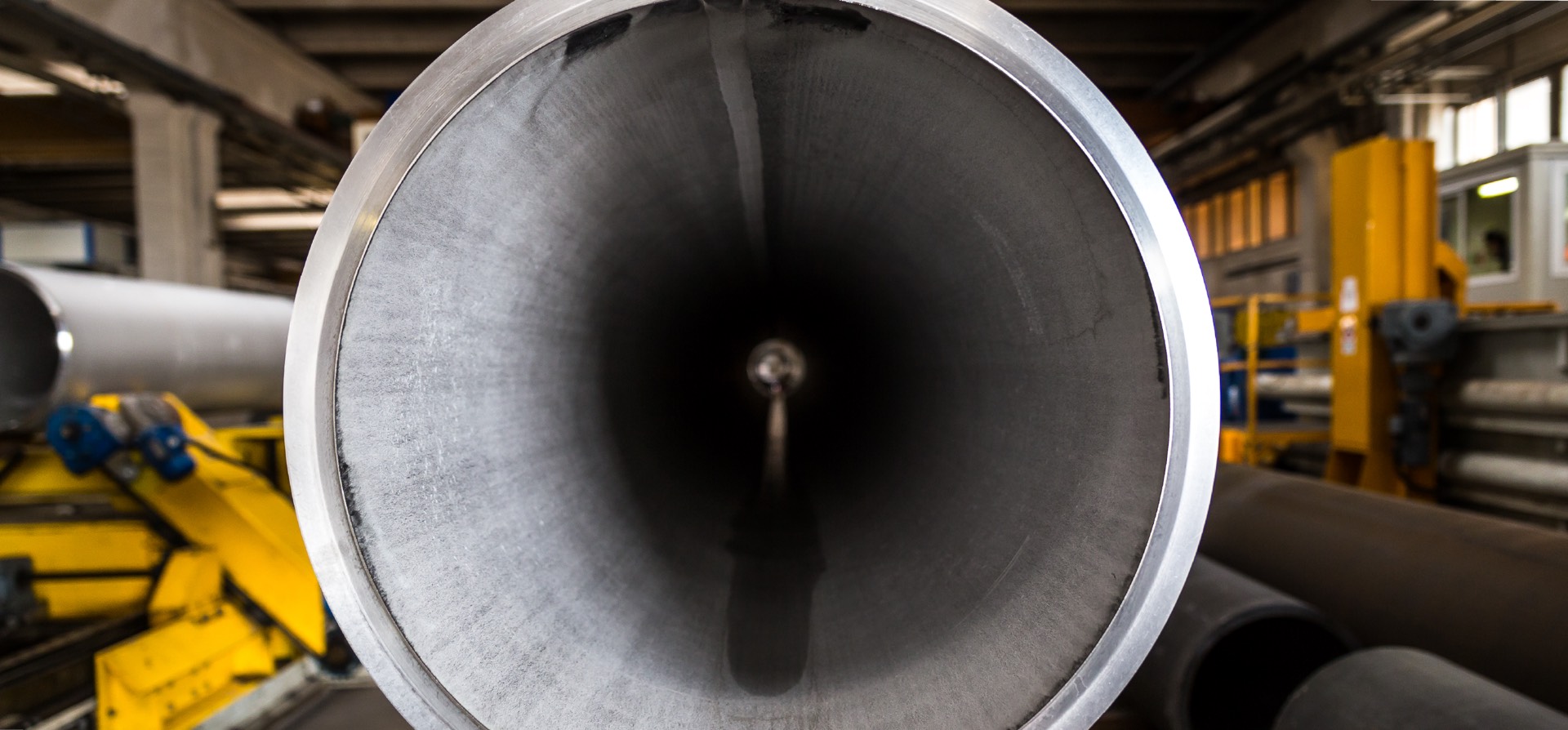

Inox Tech produces longitudinally welded pipes with wall thickness up to 100mm and outside diameter up to 110’’ manufactured from quarto plates. Plates are bent by means of forming process and rolling machines. Inox Tech uses JCO bending process. The process is excellent to produce small diameter pipe with heavy wall thickness as well as large outside diameters. To prevent rust corrosion, during transportation at final construction site, pipes are packed in suitable seaworthy packing. The entire production line is controlled by a computer system which monitors every step of the production process, from precision cutting and folding to welding and calibrating. This system also ensures that products are manufactured according to customer specifications and guarantees full traceability of the products.

We put all our strength to manufacture

the strongest material

By means of 6 bending presses with a maximum power of 6000 Tons Inox Tech manufactures longitudinally welded pipes in 300 Series, Duplex & Superduplex, Nickel Alloys, 6Moly, Carbon Steel, Low Alloy, CLAD from 6’’ to 110’’ outside diameter, wall thickness up to 100mm and length up to 12.5mtrs.